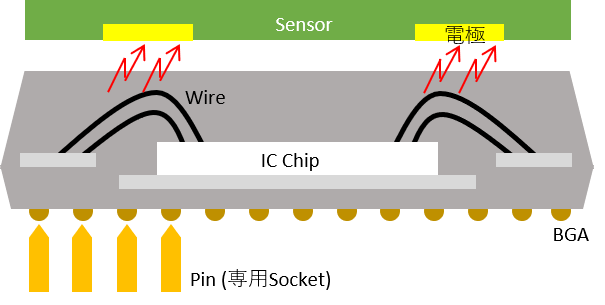

半導體

非接觸金線檢查機

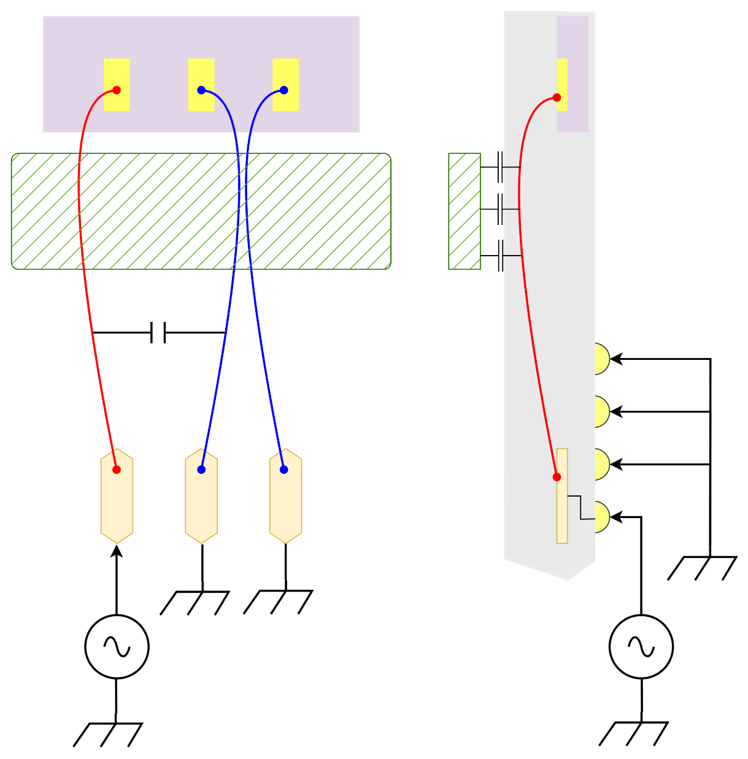

封裝完成後,利用電容耦合 Sensor 檢出 Bonding Wire 的 Wire-Close/短路,免探針、不傷樣品。

- 流程:選取被測接腳 → 施加訊號 → 讀取 Sensor訊號 → 與基準訊號數據比對 → 輸出 Pass/Fail。

- 優勢:非接觸、快速掃描、可量產導入,提升終檢良率與追溯效率。

- 適用:WB BGA IC、Molding制程檢驗、密線區封裝之出貨終檢與 FA 驗證

non-contact bunding wire ispection system.

AFTER PACKAGING IS COMPLETED,

A CAPACITIVE-COUPLING SENSOR DETECTS BONDING-WIRE”WIRE-CLOSE

“/SHORT DEFECTS-PROBE-LESS AND

NON-DESTRUCTIVE.

A CAPACITIVE-COUPLING SENSOR DETECTS BONDING-WIRE”WIRE-CLOSE

“/SHORT DEFECTS-PROBE-LESS AND

NON-DESTRUCTIVE.

• PROCESS:

Select target pin → apply signal → read sensor output → compare to →output PASS/FAIL.

Select target pin → apply signal → read sensor output → compare to →output PASS/FAIL.

• Advantages:

Non-contact, fast scanning, production-line ready; improves final-test yield and traceability.

Non-contact, fast scanning, production-line ready; improves final-test yield and traceability.

• Applications:

Wire-bonded BGA ICs; post-molding inspection; outgoing final test and FAverification for find pitch/high-density wire-bond packages.

Wire-bonded BGA ICs; post-molding inspection; outgoing final test and FAverification for find pitch/high-density wire-bond packages.