半導體

非接觸金線檢查機

- 流程:選取被測接腳 → 施加訊號 → 讀取 Sensor訊號 → 與基準訊號數據比對 → 輸出 Pass/Fail。

- 優勢:非接觸、快速掃描、可量產導入,提升終檢良率與追溯效率。

- 適用:WB BGA IC、Molding制程檢驗、密線區封裝之出貨終檢與 FA 驗證

Advanced Non-Contact Bonding Wire Inspection System

Overview:

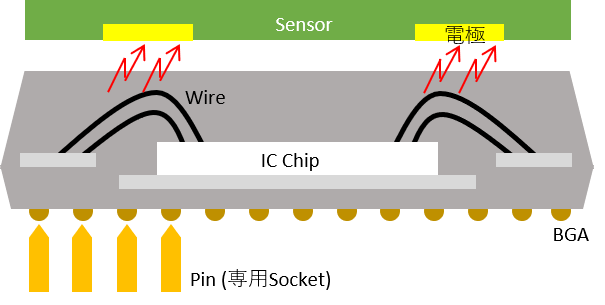

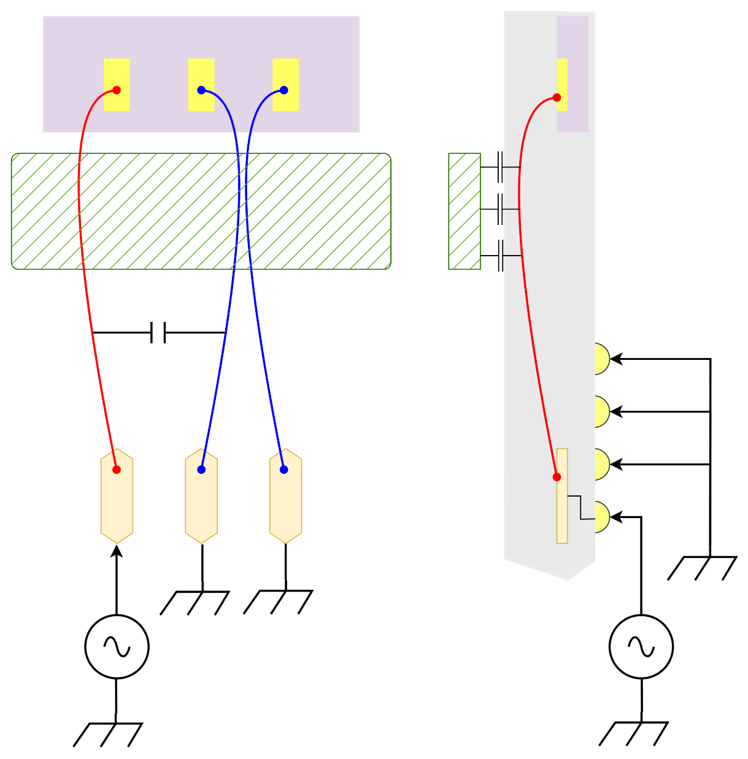

After IC molding, a capacitive-coupling sensor is used to non-contact detect bonding wire proximity (wire-close) and shorts.

Signals are input from the Ball Grid side and detected by the non-contact sensor, allowing measurements without damaging the sample.

Inspection Process:

Select the target pin → Apply signal → Read sensor signal → Compare with reference data → Output Pass/Fail judgment.

Features & Benefits:

・High-speed scanning enabled by non-contact signal detection

・Easy inline integration into production lines

・Contributes to improved yield in final inspection and more efficient traceability.

Application:

・Post-IC molding process inspection of wire-bonded (WB) BGA

・Final pre-shipment inspection after sealing high-density WB wiring areas

・Yield improvement through feedback to the process via failure analysis (FA).