半導體

3D檢量測系統

3D檢量測系統

興城提供不同精度的3D檢量測方案,提供半導體與封裝製程中,任何需要進行3D檢測的缺陷。

系統特性

- 超高解析度與高產能檢測 ( 可依客戶規格要求客製 )。

- 3 μm 級 Z 軸解析,符合高標準製程。

- 即時檢測,防止良率損失。

- 數據精準量化,降低誤判。

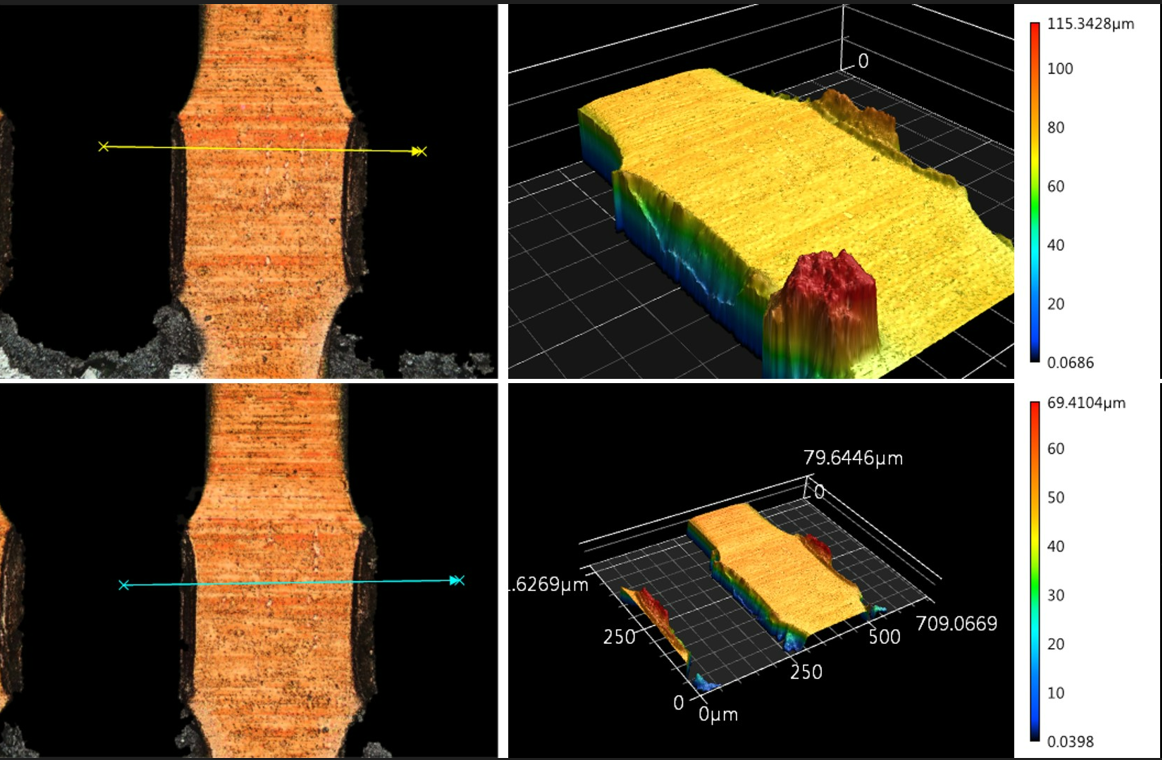

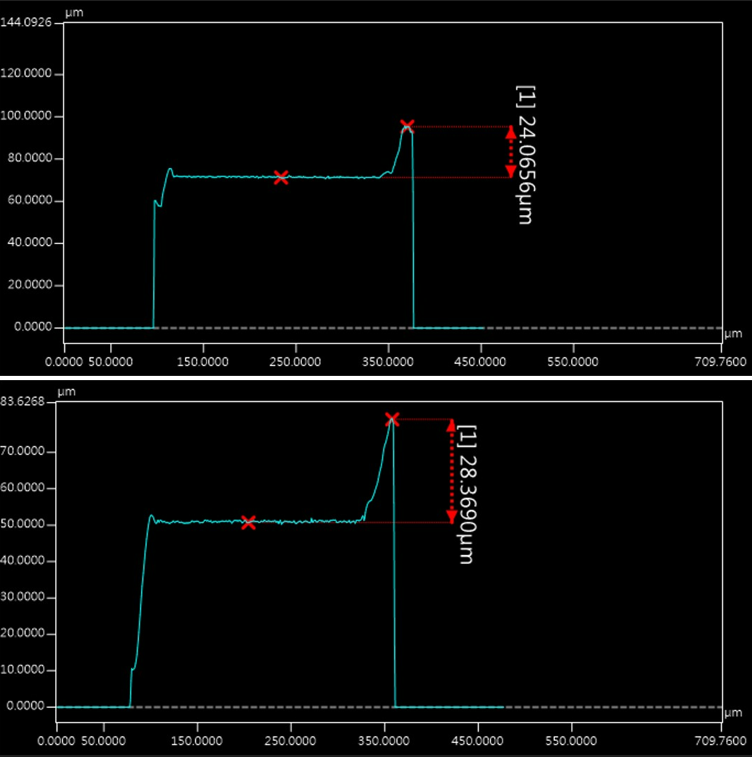

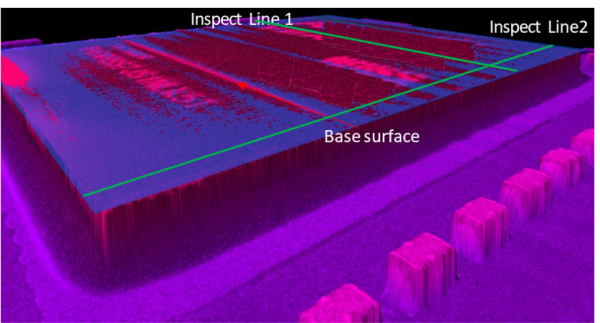

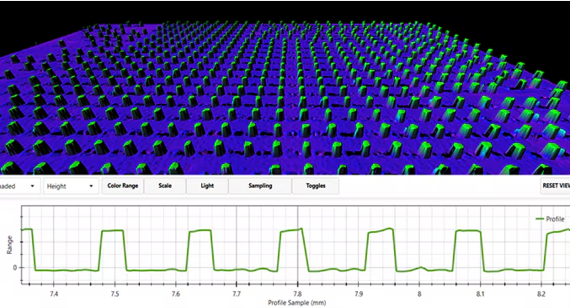

- 檢測表面缺陷 3D 輪廓,搭配 Profile 曲線呈現。

- AI 智能判別選配,強化自動化檢測。

- 客製化設備結構配置規劃。

適用場域

- 測量 Underfill 點膠寬度、高度與流動性,支援周邊與被動元件同步檢查。

- 翹曲檢查。

- Wire Bond 線寬、弧高。

- Bump 高度、尺寸、平整度。

- SMT 立碑、Shift、缺件異常。

- Socket 異常、錫附著、磨耗偵測。

- 任何立體物件之檢量測。

High Accuracy 3D Underfill Measurement

3D Inspection System

We offer a range of high-precision 3D inspection solutions for semiconductors and OSATs to meet any 3D inspection need in production.

System Features:

- Ultra-high resolution and high throughput detection (customizable to meet customer standards).

- 3μm Z-axis resolution can meet advanced process requirements.

- Real-time detection to prevent defects in the process.

- Quantitative data analysis to reduce false positives.

- 3D surface defect detection provides contour data.

- Use AI to assist defect classification to enhance auto-Inspection.

- Customizable device configurations and layouts.

application:

- Underfill width, height and fluidity of the bottom fill dispensing, and Inspection of surrounding components.

- warpage detection.

- Wire bond height and radian inspection.

- Bump height, size and coplanarity.

- SMT passive component tombstones / billboards and shift inspection.

- Socket pin abnormality, tin loss, and wear detection

- Measurement of any 3D object.